25

recovery at the wingtips, maximising

efficiency for a given span and root

bending moment. They are heavily raked

to maintain attached flow through partial

vortex lift at high wing loadings,” de

Villiers says.

Several aerofoil sections with different

thickness-to-chord ratios at different

positions along the span help to optimise

the behaviour of the structure under

aerodynamic loads. The aerofoil sections

are drawn from a library and customised

to form the final design, this detailed work

having been carried out by D3 Applied

Technologies, which Carbonix describes

as a leading aero optimisation team.

As standard, the winglets are integral

with the wing, but they can be made as

separate detachable parts as an option.

Again as standard, they are made

from carbon fibre-reinforced epoxy, but

the customer can specify glass fibre

reinforcement to make them transparent

to radio signals so that they can house

antennae. The transition to glass happens

seamlessly at the lay-up stage, so that

the structure remains continuous.

The fuselage cross-section is essentially

trapezoidal, a shape selected to maximise

internal volume while keeping drag-

inducing wetted area (skin exposed to the

airflow) to a minimum. It has a flat bottom

and vertical sides that taper inboard as

they go up to meet the wing, while the

fillet between bottom and sides is varied

along the length of the fuselage. Tapering

the fuselage cross-section below the wing

helps to manage pressure distribution

in a manner analogous to the area rule,

although strictly that rule applies at much

higher speeds.

“This is an example of a detail that

called for specialised expertise in tooling

design, to allow the fuselage and wing

roots to be moulded in one piece and

still be released from the mould,” says

Dario Valenza of Carbonix.

Structural members

The central fuselage and blended wing

route moulding features a bonded-in

tubular carry-through spar, while the

outer wing sections each have a single

spar that consists of a transverse foam

sandwich panel with carbon shear webs

and a foam core.

“During development of the airframe

we experimented with different solutions,

such as a moulded I-beam spar

laminated into the structure, and a

Nomex honeycomb panel construction,”

says de Villiers. “The current

configuration reflects the best trade-off

between structural efficiency, toughness

and cost.”

The central fuselage and wing root

structure is a moulded stressed-skin

monocoque with optimised fibre layout

and patching, and the carry-through

spar is bonded in while the fuselage

skins are in the mould. Other integral

structural components include the

engine bulkhead, a ring frame to locate

the motor controls and what de Villiers

describes as a partial bulkhead that

doubles as the front end of the fuel tank.

The top of the tank also forms part of

the payload shelf. Making every piece of

structure serve more than one purpose in

this way minimises weight and maximises

structural efficiency, he says.

Unmanned Systems Technology

| June/July 2016

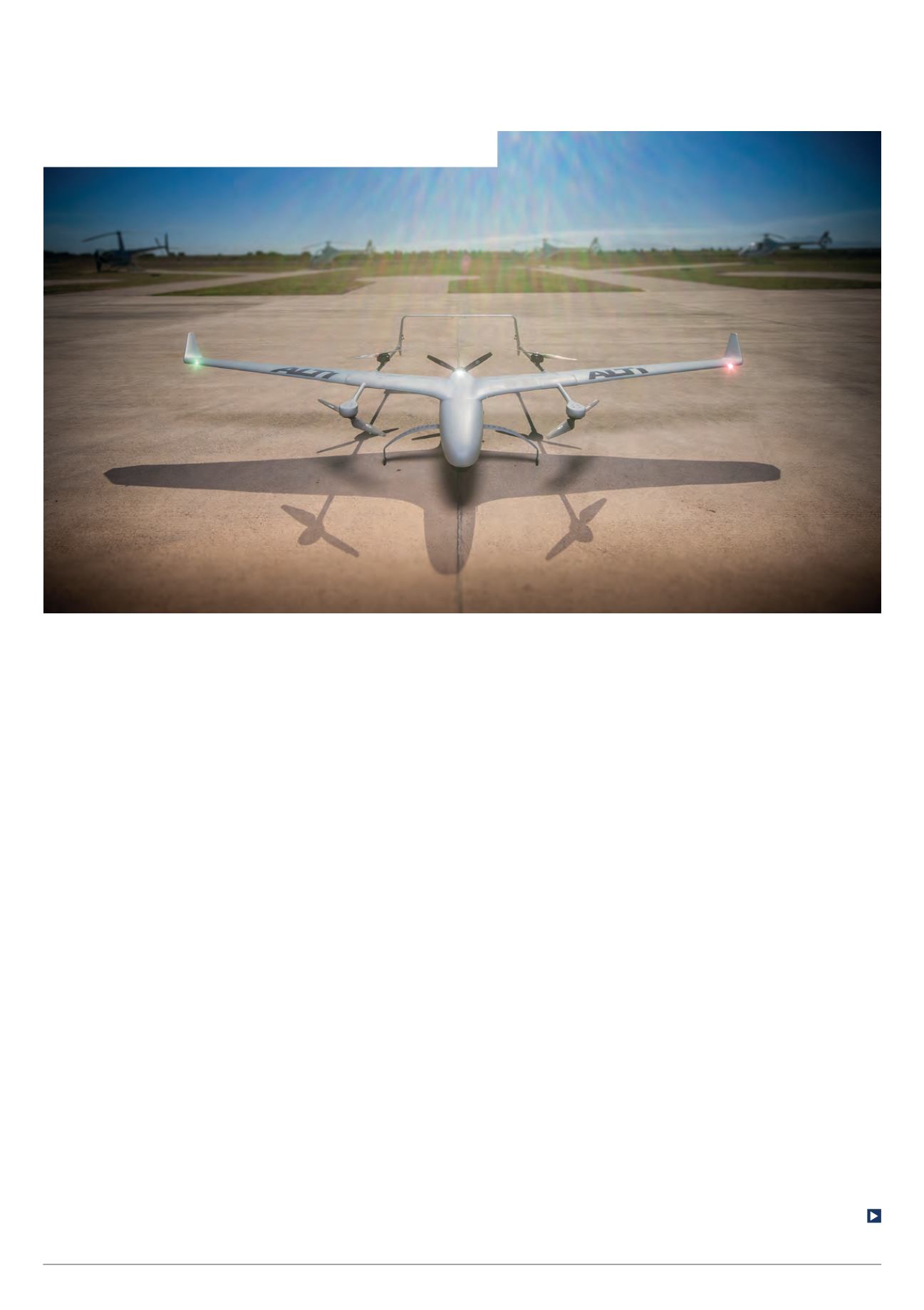

Transition sits on its fixed gear, the lack of wheels emphasising that it is a VTOL-

only machine. The front two legs are shaped to help generate lift in forward flight