69

Insitu N20 UAV 50 cc two-stroke single

|

Dossier

the oil metering pump. It incorporates

logging of key engine parameters, and

all sensors have redundancy. The ECU

has what is described by Cathcart as

“advanced diagnostics”.

The ECU stores all engine data, while

selected information is transmitted to the

operator in real time. A diagnostic port

allows data to be downloaded directly

from the ECU when the craft is parked.

Data from all operations is logged,

with software run on the operator’s PC

automatically able to recalculate the life

of individual components in the light

of ongoing operation and providing

diagnostic information.

Thus can the operator carry out their

own checks and any required field

maintenance. The only routine between-

service replacement items are the

air filter and the spark plug, and both

are accessible by removing the cowl.

Extending the time between overhauls

was a key target, to minimise the need

for field maintenance.

“A lot of incidents are post-field

maintenance,” notes Beloy. “Through

robust design we have minimised the

in-field maintenance requirement – even

our muffler is maintenance-free.”

The N20 in operation

The N20 project began in mid-2012, and

Orbital’s UAV engine division – Orbital

UAVE – started design work in July 2013,

just after being awarded the contract.

At the start of the project Orbital used

rapid prototyping to create representative

engines to investigate aspects such

as bore and stroke possibilities; this

validated its simulation work.

The first proper prototype was

assembled in time for bench testing

at Insitu in June 2014. The engine was

certified as flightworthy in January 2015,

and was first flown in April 2015. The final

prototypes – production-representative

engines – were built at Orbital in

December 2015. By the end of 2015 the

development programme had used

dozens of engines, and there had been

over 7000 hours of test running.

Orbital had run numerous durability

tests, matching FAA requirements for

manned aircraft engines, and the N20

had come through with flying colours.

The aim is to be prepared to certify it

for aviation use should the FAA’s remit

be expanded to include engines for

unmanned aircraft, which is anticipated

in 2017. “This could be the first engine

certified for unmanned use,” says Beloy.

“Already we have achieved our

durability target – now we will see how

far we can go,” he adds. “In the past we

have seen detonation in a conventional

spark ignited jet fuelled two-stroke but

not in this engine, even when we have

pushed to try to induce it.”

The N20 runs from 3000 to 6500 rpm

and is rated at 2.4 kW at 6500 rpm take-

off power. It cruises in the 3500-6500

rpm range and can operate from -30 C

to +49 C and at altitudes up to 20,000 ft.

Thanks to its innovative design around

Orbital’s unique FlexDI technology, it

promises to set a new benchmark for

engines of its type.

Unmanned Systems Technology

| June/July 2016

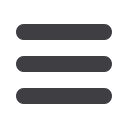

An external starter is used to

fire up an N20 on a test rig

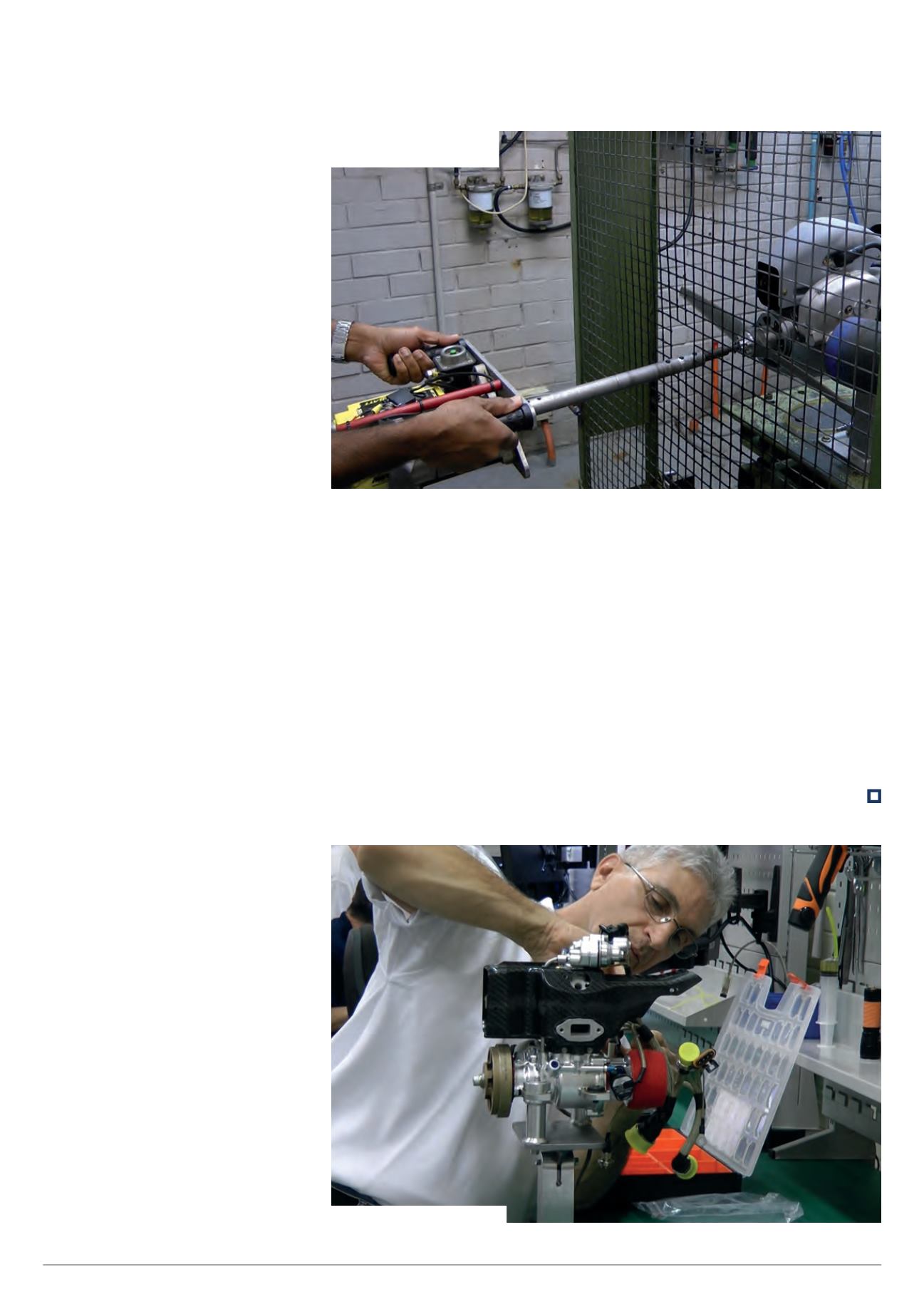

Assembly of an N20 at Orbital