62

operating range and is very tolerant of

changing conditions.”

Cathcart reports that the robustness

of FlexDI is such that engine calibration

doesn’t have to be individually tailored

to each example of a production

engine batch. That means there is no

requirement for any end-of-line tuning.

Kerosene-based heavy fuel is low

in octane rating, which means it has a

propensity to knock; using FlexDI, the

fuelling can be tailored to avoid knocking.

In effect, the amount of time the fuel

spends in hot chamber conditions can

be reduced by delaying the injection

event. This ability to avoid knock enables

the use of a compression ratio in excess

of 10:1, which in turn provides improved

fuel efficiency.

Beloy notes that the fuel efficiency

advantage of the N20 is seen most

prominently when the craft is in cruise

and loitering modes. He adds, “A further

advantage of FlexDI is that since the

engine can maintain robust, reliable

combustion across a relatively wide

range of cylinder temperatures, an active

cooling system is not required and

wider temperature limits are established,

affording users the ability to operate the

rest of the system without the need to

constantly monitor engine temperature.”

This, Beloy notes, is particularly significant

in the case of a UAV, which typically

experiences a wide temperature variation

between ground level and flight altitude.

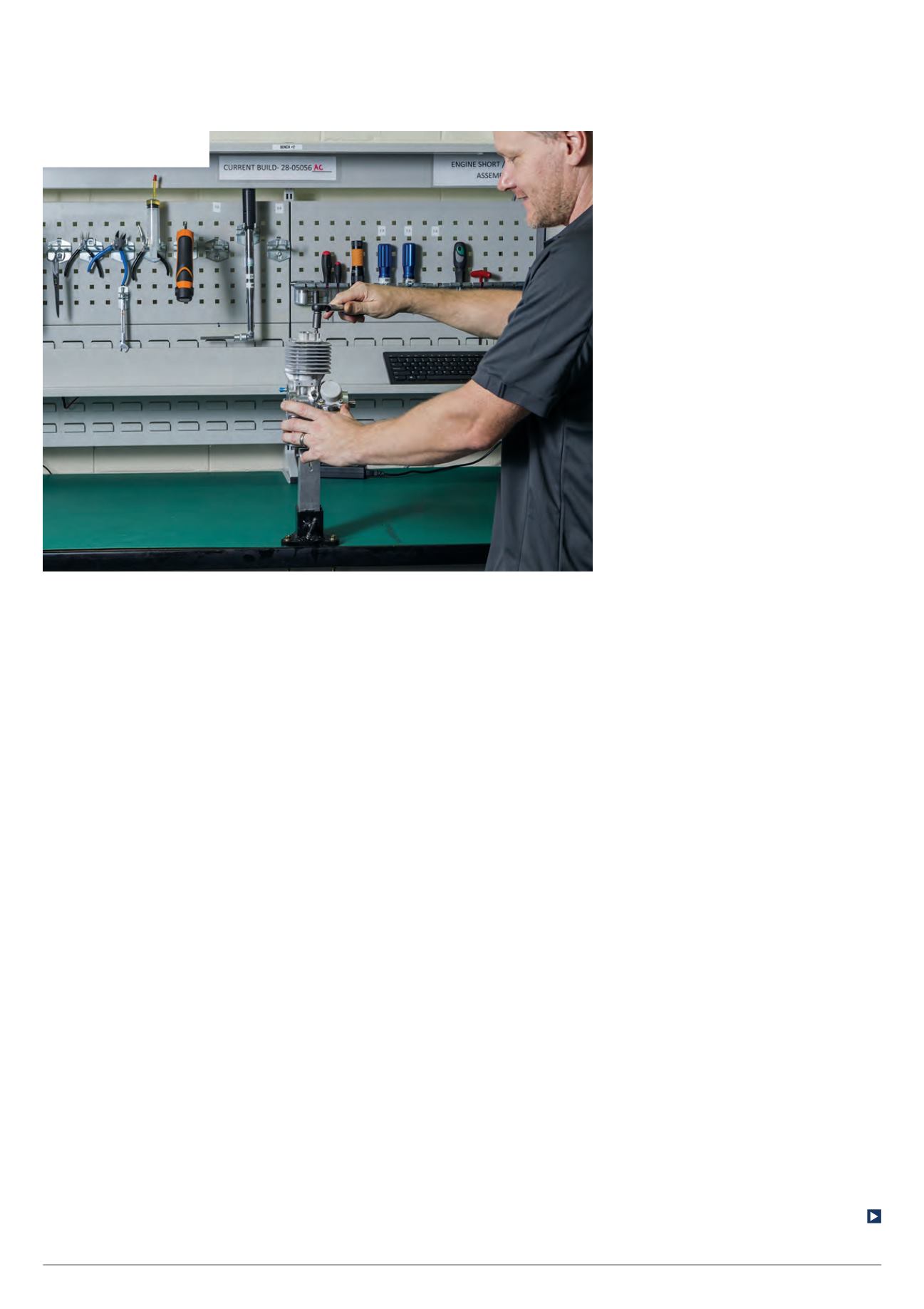

N20 FlexDI fuelling system

The N20 draws air into its crankcase

through an air filter, a throttle body with

a butterfly throttle and a reed valve (in

that order). Cathcart notes that intake

tuning revolves around the length of the

throttle body and its interaction with the

air filter. However, he adds that “most

tuning is on the exhaust side”, as with

any two-stroke that exploits pressure

waves to enhance cylinder scavenging

and thus cylinder filling.

The relative simplicity of a reed valve

compared with a rotary is seen as

advantageous in terms of saving weight.

At the same time, its inherently superior

response at lower engine speeds is seen

as the basis of a flatter torque curve,

which is considered more important than

any peak power gain that could be made

by using a rotary valve.

The exhaust port is to the right-hand

side of the cylinder, while the transfer

ports are adjacent, four in total – two

main outer ports sandwiching a pair of

secondary ones. The transfer ports are

arranged to create loop scavenging.

Avoiding the need for a piston crown

deflector, loop scavenging directs

the incoming charge air towards the

combustion chamber such that it

follows its curvature and is deflected

downwards again. Thus the air makes a

loop that discourages it from escaping

through the exhaust port but helps push

out the exhaust gas and at the same

time creates a swirling turbulence that

enhances combustion.

The combustion chamber in the N20

head is a recess with a tapered squish

band as its extremity. The form of the

piston crown is undisclosed. The fuel

injector is vertical and on the central axis

of the cylinder, while the plug is angled

at 45

º

and is located above the exhaust

port. Both the injector and the plug enter

the chamber in the recess, which can

accept either one or two plugs.

The FlexDI fuel injector has twin,

independently controlled solenoids. An

upper solenoid meters the fuel supply into

the chamber where the compressed air

is admitted; a lower solenoid controls the

outward-opening pintle that admits fuel

to the combustion chamber. The air can

only flow when the pintle opens and, as

noted, it carries the fuel into the chamber.

Beloy remarks that a lot of

development has gone into fuel delivery,

in ensuring that pick-up in the fuel tank

works down to a very low level despite

the g-forces to which a lightweight UAV

is subject in flight. This has meant paying

close attention to the control of slosh in

the tank and to the pick-up position. It

has also led to the use of a header tank

inside the main tank.

Fuel is supplied by an electric

pump submerged in the header tank

to a pressure regulator in the fuel rail

assembly atop the N20. The pressure

regulator has a spring-loaded diaphragm

that lifts to return excess fuel to

June/July 2016 |

Unmanned Systems Technology

Dossier

|

Insitu N20 UAV 50 cc two-stroke single

The N20 two-stroke has air

cooling of its single cylinder