60

Dossier

|

Insitu N20 UAV 50 cc two-stroke single

existing engine used in the ScanEagle,

Insitu wanted a larger displacement for

greater take-off power, and for the same

cruise power level to lower the engine’s

operating speed. That in theory would

enhance reliability and fuel efficiency,

and reduce vibration and (propeller and

engine) noise levels. Running slower also

allows use of a larger diameter propeller,

which is more efficient as well as quieter.

Consequently the move was made

from a 28 cc to a 50 cc displacement.

Beloy says, “The weight penalty

associated with that increase is marginal

considering the improved specific fuel

consumption provided by Orbital’s direct

injection system. Moreover, the larger

displacement of the N20 can provide

additional climb power for heavier

payloads, for more extreme applications

as well as significantly more electrical

power for more demanding payloads.”

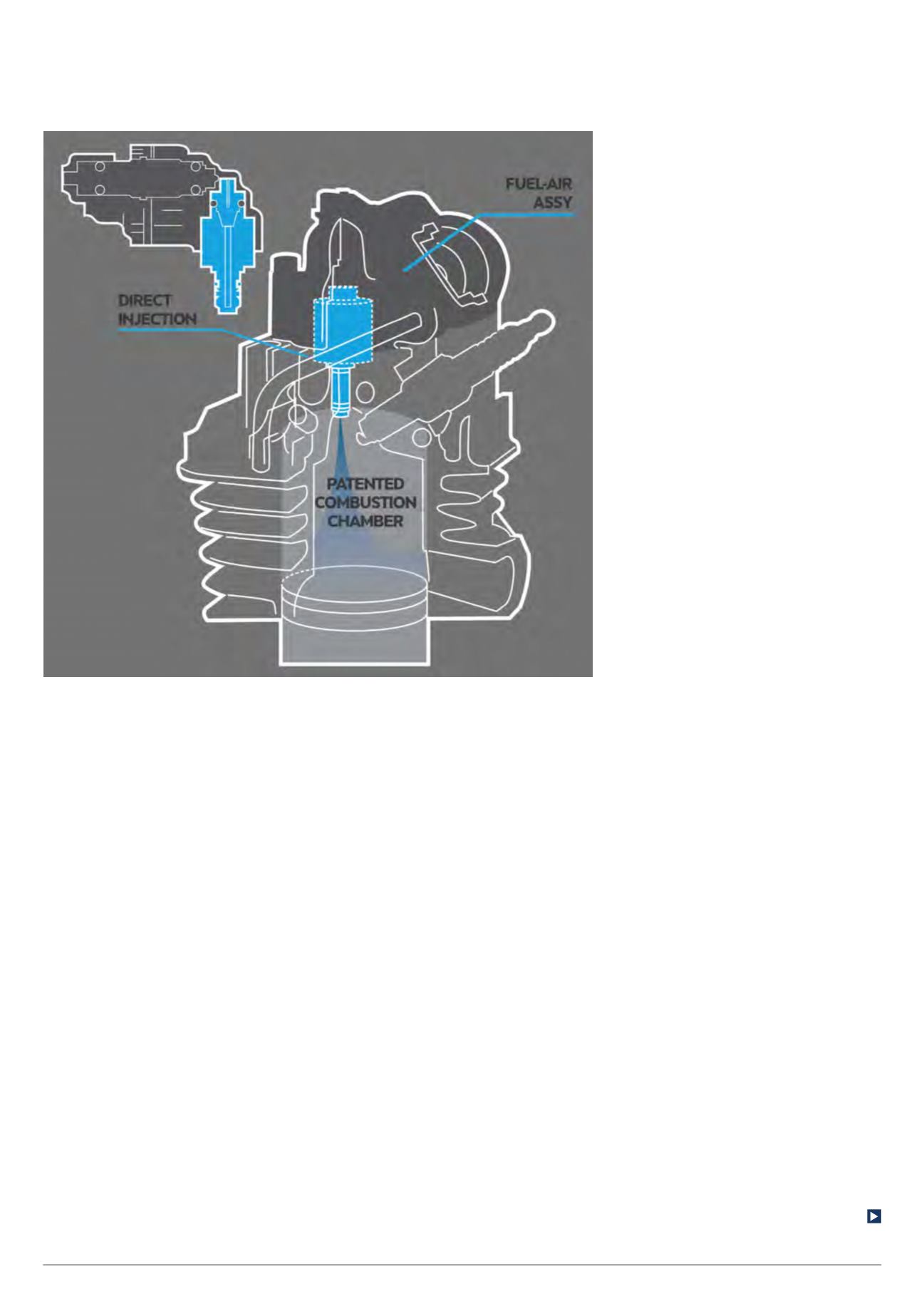

FlexDI

Orbital calls its unique compressed-air

assisted DI, which is used in conjunction

with its own spark ignition and engine

management systems, FlexDI. The

engine management system embraces

its own ECU, sensors and attendant

actuators. It has had a number of

different applications, starting with a two-

stroke Mercury marine engine in 1996

and including high-volume applications

such as two-stroke scooters made by

Aprilia and Piaggio. Its reliability and

effectiveness are thus well proven.

There have been two- and four-stroke

applications of FlexDI. Orbital’s chief

technology officer Geoff Cathcart admits

that over the years the advantage of

FlexDI has proved greater in two-stroke

than in four-stroke applications. Typically,

he says, a two-stroke switching from port

injection can obtain a 50% reduction in

fuel consumption and a 90% reduction

in emissions.

He explains that in the case of a

port injected two-stroke, a significant

proportion of the fuel-oil mixture in the

incoming charge is lost from the cylinder

through the exhaust port during the

scavenging process. Using FlexDI instead

there is no fuel in the charge during the

scavenging phase, and excess air can

be used to help extract spent gas.

The basic approach to injection is that

of stratified charge combustion, with the

incoming fuel being spray-guided. The

ingress of fuel is assisted by a dedicated

compressed air supply running through

the delivery nozzle. The pressure of the

compressed air transports the fuel into

the combustion chamber, in the process

creating very small droplets.

Cathcart says, “Think of an aerosol

spraying a very well atomised mist.

The air accelerates as it expands,

and that acceleration shears the fuel

droplets, creating a very finely atomised

mist. Compared with the 120 microns

representative of port injection, our

average fuel droplet size is 8 microns,

which is the industry benchmark.”

Cathcart notes that in the case of

conventional high-pressure direct

injection, the fuel is broken up by fine

holes in the delivery nozzle, which

doesn’t inherently create as good

atomisation as FlexDI.

“Rather than having an inward-opening

nozzle with many small holes, our

outward-opening pintle acts like a poppet

valve, forming an annulus through which

the fuel is sheared by the action of the

compressed air. Our fine atomisation

results in better vaporisation through

increased surface area of the fuel,” he

says.

“Heavy fuel is less volatile than

gasoline, so is much harder to spark-

ignite. Given our droplet size, spark rather

than compression ignition works fine.

Owing to the atomisation we obtain, and

the fact that we keep the fuel off the cold

bore wall, heavy fuel can be spark ignited

down to -30 C in 5 s or less without

the need for a glow plug or similar. Our

stratified combustion provides a wide

June/July 2016 |

Unmanned Systems Technology

Schematic of Orbital’s FlexDI compressed-

air assisted direct injection