59

were already a leader in reliability

through development of the existing

engine, but we wanted to push the bar

with the N20. The goal is zero engine

failures, especially as any failure can

cause the loss of an expensive payload.

“We have more than 20 years of

learning from the development and

operation of our existing engines. The

N20 is a combination of our experience

and that of Orbital.”

Overseen by Insitu, Orbital drew the

N20 from the aforementioned clean sheet

of paper. Since Insitu funded the project

it owns the IP, aside from the proprietary

incorporated Orbital DI technology.

The 50 cc N20 produces 2.4 kW. It

runs on Jet fuel (A, A1, JP5 and JP8)

while an N21 version runs on certain

types of gasoline or Avgas, although the

only difference between the two is in the

engine calibration firmware. The engine

is air-cooled, has an upright cylinder and

is used as a pusher in the ScanEagle (in

other words, the propeller is at the rear).

The engine core has been designed

to be adaptable to a variety of airframes,

of which the ScanEagle is the first. The

engine core is augmented by a fuel

supply system, an oil supply system,

a muffler, a generator, a propeller

and an engine management system.

Orbital supplies the fuel pump, the

fuel injector and the ECU while Insitu

has collaborated with a propeller

manufacturer to develop an application-

specific item.

“The N20 has already met all its targets

in respect of power, fuel consumption

and reliability,” Beloy reported as

this article was being written, and

preparations were in hand for the first

production examples to begin operation.

Engine design

considerations

We asked Beloy, given the clean-sheet

approach, why not opt for a change

of engine type, perhaps to something

more radical?

“Reliability is the chief requirement,”

he explains. “There was the temptation

to use something different but it was

considered more important to use well-

proven technology.” Supercharging and

turbo-supercharging were ruled out on

grounds of cost and reliability, as well

as added weight, size and complexity.

“We make sufficient power without the

additional complexity,” he says.

A compression ignition engine would

require a higher compression ratio,

and with that a stronger, heavier engine

architecture, and it would create more

vibration, hence the preference for

continuing with spark ignition. “However,

it must in all circumstances be possible

to ignite jet fuel in a controlled manner,

and Orbital’s technology does this,”

Beloy emphasises.

Spark ignition of jet fuel normally implies

running hot, which in turn causes the

build-up of deposits in the combustion

chamber. That not only reduces the time

between overhauls but also brings a

danger of pre-ignition. Orbital’s technology

makes the engine run cooler, overcoming

this drawback. It also helps meet the key

challenge of the vast range of operational

conditions to which the ScanEagle is

subject, from the cold of the Arctic to the

heat of the desert.

The ScanEagle has always been

powered by an air-cooled two-stroke single.

It was originally powered by a modified

model aircraft engine, although that 28 cc

unit has been much modified over time.

Insitu wanted to stay with an air-cooled two-

stroke in consideration of power density.

Minimising weight was a key target,

hence the continuing use of just one

cylinder. Compared with a twin, a single is

lighter and more fuel-efficient. It also implies

a craft with less aerodynamic drag and

helps make the engine more affordable.

However, compared with the

Insitu N20 UAV 50 cc two-stroke single

|

Dossier

Unmanned Systems Technology

| June/July 2016

We wanted to

push the bar

with the N20.

The goal is zero

engine failures,

especially as any

failure can cause

the loss of a

costly payload

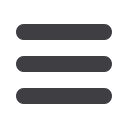

The powertrain package

for Insitu’s ScanEagle UAV

incorporates the N20 into a

module that can be removed

from the craft without

disconnecting any fluid lines