48

Show report

|

AUVSI’s Xponential

14,000 rpm with no failures, while most

customer applications call for 6000-9000

rpm.

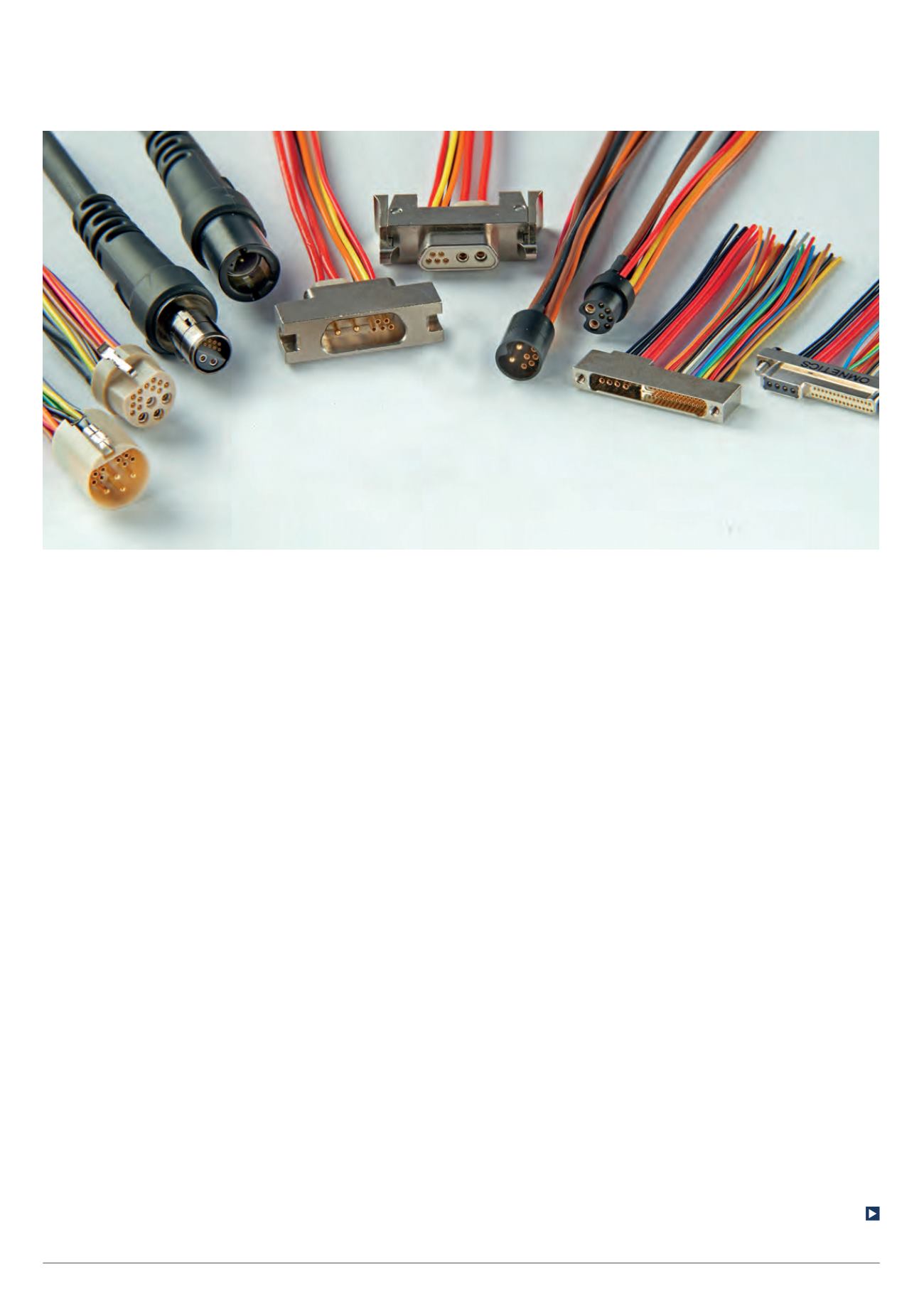

Omnetics makes wiring for

unmanned

vehicles, and Bob Stanton

told us that the latest trend is for so-

called ‘hybrid’ cables and connectors

that run signal and power lines together.

This is to reduce the space taken up

and, more important, the weight of the

wiring on a vehicle, taking advantage of

the reduced current requirements of the

latest chip technology.

“The connectors can be right down

to ‘Micro’ 1.27 mm pitch and ‘Nano’

0.635 mm pitch sizes,” Stanton explained.

“We are now running signal and power

pins side by side in these, so you have

only one cable and one connector

where before you had two. In addition to

shielding for the power and signal lines

we have had to introduce differential

signal processing to enable us to use

a hybrid cable for high-speed digital

equipment such as surveillance cameras

and GPS data processing.”

Stanton also noted that, more and

more often, the miniature hybrid

connectors use the latching type

rather than the traditional jack screw

connection. “The latest technology

cam and spring latch matches the

performance of the MIL-SPEC jack

screw connection and allows for quicker

and easier switching of modules in the

field.”

Uvionix’s Alpha project to develop

a pair of small, internet-connected

electric UAVs for utility inspection

and commercial package delivery is

on schedule to be ready in 2017, the

company’s Boris Iskrev told

UST

at the

show.

Both applications require a high

degree of inherent safety around

equipment and people, and Iskrev

was keen to emphasise the layers of

redundancy and remote supervision

integrated into the autonomous, 8 lb,

27 in diameter aircraft, which is designed

to carry a payload of up to 2 lb, fly for

up to 80 minutes and cover a six-mile

return-mission radius.

The Alpha multi-purpose aerial

platform should be ready at the

beginning of next year, he said, while

the delivery vehicle and the ‘ecosystem’

that supports the delivery service is

set to follow by mid-year, ahead of any

favourable decision by the US FAA on

easing the stipulation that commercial

UAVs must remain within line of sight of

the pilot and observer.

The platform’s two rotors are coaxial

and counter-rotate inside a protective

shroud, and each is driven by its own

neodymium permanent magnet motor

and powered by a high power-density

lithium-based battery based on a

commercially available chemistry that

Iskrev says is new to UAVs.

Four control surfaces attached to

cross-pieces underneath the rotor can

generate roll, pitch and yaw forces,

although yaw is normally controlled with

torque reaction from differential rotor rpm.

This unusual configuration led Uvionix

to develop its own autopilot software and

two controllers, the first being a real-time

system to stabilise and manoeuvre the

vehicle, the second to communicate over

the internet with the control centre and

perform more complex algorithms such

as visual pattern matching to find landing

sites autonomously.

The company developed the second

controller using an NVIDIA Jetson TX1

embedded platform. The controller

June/July 2016 |

Unmanned Systems Technology

Omnetics’ range of hybrid’ connectors

run power and signal lines together