82

Monocrystalline solar cells are made out

of silicon ingots, which are cylindrical

in shape. To optimise performance,

four sides are cut out of the cylindrical

ingots to make silicon wafers. Unlike

monocrystalline-based solar panels, for

poly-crystalline solar panels raw silicon is

melted and poured into a square mould,

which is cooled and cut into perfectly

square wafers. Some crystalline materials

have been used on UAVs but it tends to

be relatively heavy, as the cells have to

be thicker, and the effciency is typically

only in the 15-18% range.

The second category is CIGS

technology, part of the class of what

would be called amorphous solar cells,

and there is also amorphous silicon. They

are not crystalline, as amorphous implies,

and because of that they tend to have

much lower effciency. So where CIGS

cells are typically in the 10-12% effciency

range, amorphous silicon would be even

lower than that, perhaps 6-8%.

Despite that limited effciency CIGS

cells are relatively light and inexpensive,

so they are suitable where effciency

is not the key factor, but as soon as

something more effcient is needed

a third category of cells, like a GaAs

type or a III-V type cell which can give

effciencies of 25-35%, is required.

Silicon is in column 4 in the periodic

table which means that silicon atoms

can bond to silicon atoms and make a

perfect crystal structure. If you move one

column left, and one column right, you

have a 3 and a 5 which can also bond

together to make a perfect crystal. This

is how Gallium and Arsine form GaAs.

There are two benefts of using a 3-5

(III-V) instead of a 4 (or silicon). First –

they work better for converting light to

electricity. This has to do with something

called the band gap of the material. GaAs

is a direct band gap material and silicon

is an indirect band gap material. The

second beneft has to do with junctions.

You can mix and match various atoms to

create new 3-5 junctions while keeping

the crystal intact. This allows for better

overall performance.

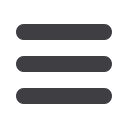

Multi-junction cells

There are two ways to make solar cells

work more effciently. One is to make each

junction better. The other is to add more

and more junctions. A junction is a layer

in the solar cell that captures a certain

portion of light better.

A typical solar cell has only a single

junction, and captures effciently only

in the wavelength that’s closest to the

properties of the materials used; for

silicon that’s infrared. Any wavelength

in the solar spectrum that has higher

energy – be it visible red, orange, yellow,

green or blue – will have progressively

higher energies per photon.

It is possible to convert all those

photons into electrical power, but with

blue photons about half the energy is

wasted in conversion in a silicon cell

because the cell is converting it at the

infrared photon energy. It’s a quantum

conversion: a cell’s quantum effciency

June/July 2016 |

Unmanned Systems Technology

The layers of an inverted

metamorphic multi-junction cell

(Courtesy of ML Devices)

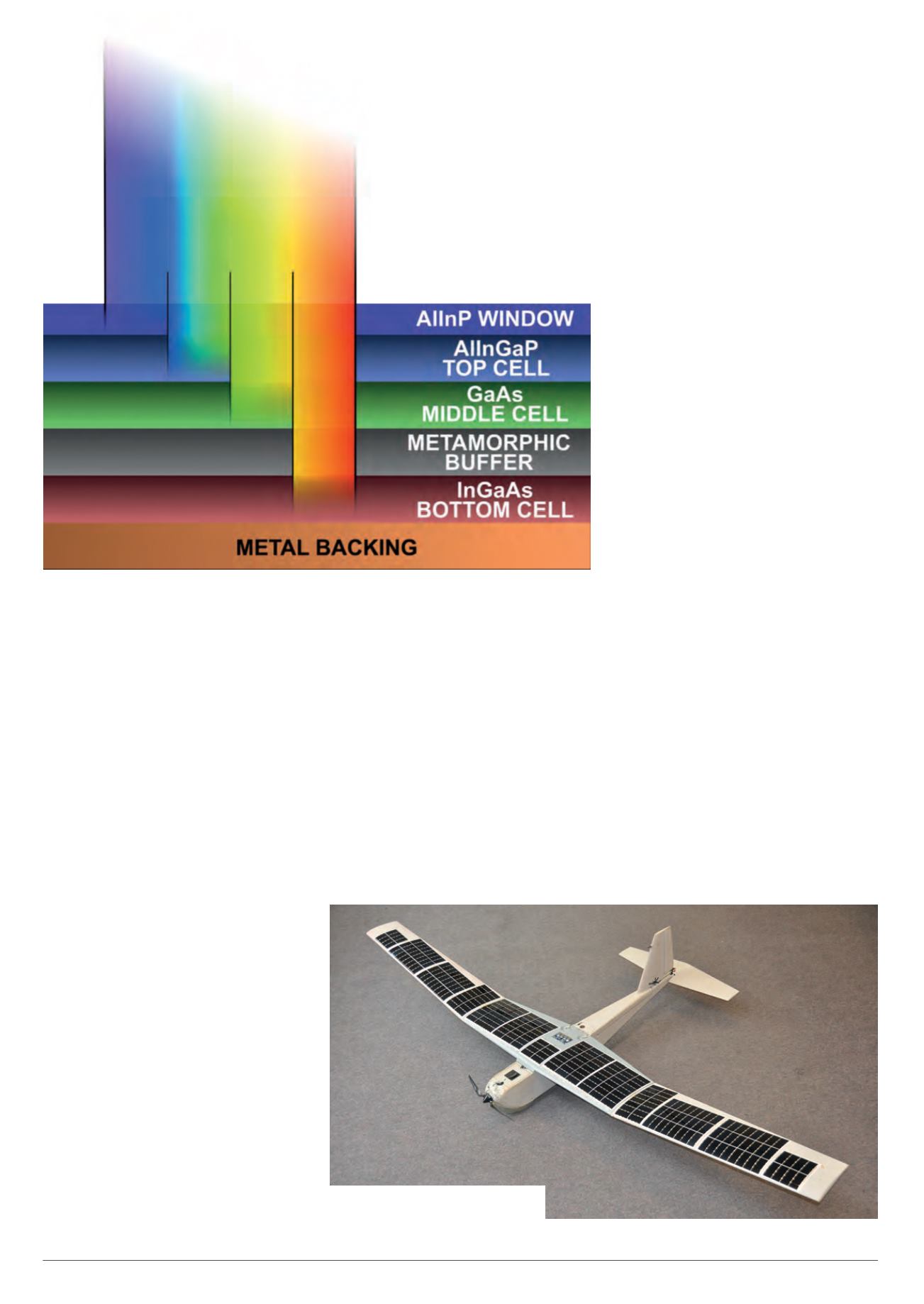

Solar panels integrated into the wings

of a UAV (Courtesy of ML Devices)